CNC GANG-TYPE LATHE

FULLY AUTOMATIC UNMANNED MACHINING FOR MANPOWER SAVING AND HIGH EFFICIENCY

The WTG-355 CNC Gang Type Lathe is equipped with a parts loader / unloader device, allowing the machine to perform fully automatic continuous machining with unmanned operation.

This machine can effectively solve the current problem of manpower shortages, while increasing machining efficiency and productivity.

Automatic Parts Loader / Unloader System

- The machine comes equipped with an automatic parts loader / unloader device.

When used together with a parts conveyor, unmanned automatic continuous machining can be achieved, saving manpower and production costs. - The jaw type feed method provides fast parts feed and retraction.

- Parts loading / unloading can be conducted with spindle non-stop, resulting in increased production efficiency.

- When turning off the parts loading function, parts loading / unloading can be operated manually. It is suitable for small batch production.

Highly Rigid Precise Spindle

- Max. spindle speed: 4,000 rpm

- Spindle motor:

Fanuc BiI 6 (standard);

Fukuta SF-112L (optional)

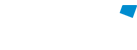

Symmetrical Structure

- The bas is a box type symmetrical design that ensures structural dependability and maintains outstanding machining accuracy at all times.

- The compact slide structure suppresses vibration, thus dramatically increasing machining stability.

- Extra large X-axis travel provides more spaces for tools.

- Extra large Z-axis helps to increase the chip exhaust capacity.

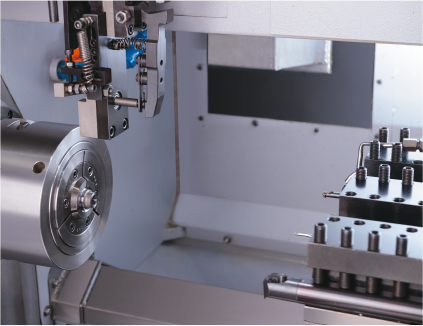

Gang Type Tooling System

- The use of gang type tooling system can eliminate turret error, which in turn boosts machining accuracy and production efficiency.

- The dovetailed tool holder locking device ensures accurate match between the tool holder and the bottom slide.

- The gang type tooling system can be fitted with 4 ~ 6 tool holders, featuring fast tool change and accurate positioning.

Machine Specifications:

| MODEL | WTG-355 |

|---|---|

| Max. swing | Ø200 mm |

| Max. turning diameter over cross slide | Ø140 mm |

| Spindle speed | 0 ~ 4,000 rpm |

| Hole through spindle | Ø55 mm |

| X-axis travel | 355 mm |

| Z-axis travel | 280 mm |

| Spindle motor | 5.5 Kw |

| Tool holder type | Gang-type |

| Tool size | □20 mm |

| Dimensions | 3,080 x 2,160 x 1,810 mm |

| Weight | 3,400 kg |

● We reserve the rights to change the product specifications, appearance, accessories or advise no longer in use.

Standard Accessories

- Parts loading / unlading device

- Auto door for operator

- FANUC controller

- Heat exchanger

- Full enclosure

- Work lamp

- LED alarm lamp

- MPG Handwheel

- Chip conveyor

- ID/OD sub-tool holder

Optional Accessories

- Optional Equipment

- Oil skimmer

- Chip cart

- High pressure coolant through center 70/120 bar

- Air conditioner for electrical cabinet

- Hydraulic power turret